Fire-protective and fire-resistive glazing sound very similar. It’s no wonder most people — even those in the construction industry — often think they are the same thing. However, that is not the case.

Fire-protective glazing and fire-resistive glazing are two different things. Their distinctions are defined by the National Fire Protection Association (NFPA) guidelines and the International Building Code (IBC).

Their differences are also determined by Underwriters Laboratories (UL) and ASTM International test standards for fire-rated materials.

These two categories of fire-rated glass used as door glazing are governed by different requirements regarding performance features, applications, and test standards. Understanding their differences can guide you in choosing the right doors and frames for your building.

Check out the infographic below to learn how fire-protective and fire-resistive glass used as door glazing differ.

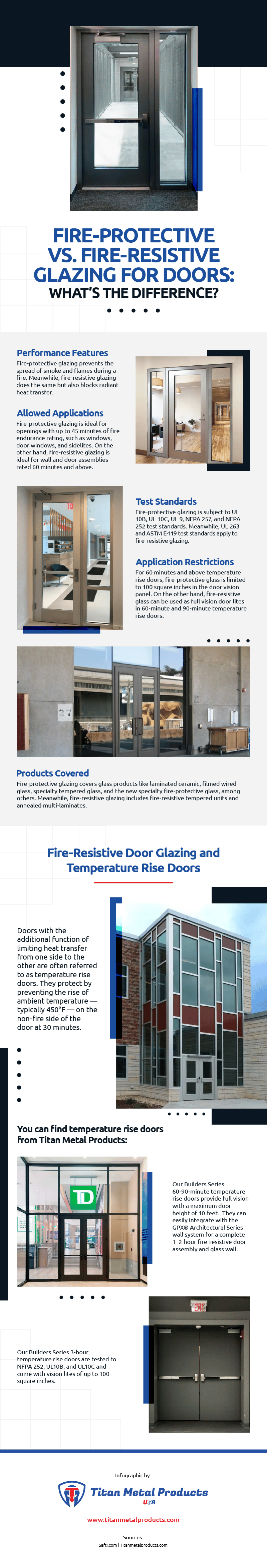

Fire-Protective vs. Fire-Resistive Door Glazing: Understanding Their Differences

When choosing a fire-rated door for your building, you must know the differences between fire-protective and fire-resistive door glazing. Here’s a guide to help keep your facility’s structures compliant with fire safety regulations.

Functions and Performance Features

Fire-protective door glazing is used to contain smoke and flames. This functionality enables building occupants to exit the building safely without the risk of smoke inhalation. This type of door glazing typically uses filmed or laminated ceramics, filmed wired glass, tempered glass, or the new clear, specialty fire-protective glazing product.

Meanwhile, fire-resistive door glazing compartmentalizes smoke and flames while blocking radiant heat transfer. Radiant heat can cause further fire breakout, igniting paper materials, drapes, clothing, or other flammable materials. Usually, the glazing is made of either fire-resistive tempered units or annealed multilaminates.

Allowed Applications

Fire-protective glazing is ideal for doors and openings with up to 45 minutes of fire endurance rating, such as windows, door windows, and sidelites. Titan Metal Products offers 20-45-minute fire-protective doors up to 10 feet tested to NFPA 252, UL 10B, and UL 10C.

The doors feature full vision glazing with standard and narrow profile choices and multiple hardware selections and finishes, including custom aluminum clad and stainless-steel clad options.

Meanwhile, our 45-minute fire-rated windows, sidelites, and transoms are available with a new clear, USA-made, and highly durable specialty fire-protective patented SuperClear 45-HS-LI (hose stream, low-iron). Listed and labeled by UL and Intertek, the fire-protective openings are tested to NFPA 257 and UL 9 for windows and NFPA 252, UL 10B, and UL 10C for sidelites and transoms.

On the other hand, fire-resistive glazing is suitable for wall and door assemblies rated 60 minutes and above and includes glazing around and over the door, such as transoms and sidelites. Fire-resistive glass is ideal for installations in stairwell enclosures, elevator enclosures, and occupancy separations.

Test Standards

Fire-protective glazing is subject to the following test standards:

- UL 10B, Fire Tests of Door Assemblies

- UL 10C, Positive Pressure Fire Tests of Door Assemblies

- UL 9, Standard for Safety Fire Tests of Window Assemblies

- NFPA 257, Standard on Fire Tests for Window and Glass Block Assemblies

- NFPA 252, Standard Methods of Fire Tests of Door Assemblies

Meanwhile, the following test standards apply to fire-resistive glazing:

- UL 263, Fire Tests of Building Construction and Materials

- ASTM E-119, Standard Methods for Fire Tests of Building Construction and Materials

Application Restrictions

The IBC provides that fire-protective glass cannot exceed 25% of the total wall area since it cannot stop the spread of radiant heat. Although there are fire-protective doors rated from 60 to 180 minutes, their application is limited to 100-inch door vision panels.

On the other hand, fire-resistive glass can be used up to the maximum size tested and has no limitations regarding its applications.

Products Covered

Fire-protective glazing typically covers the following products:

- Laminated safety ceramic (20–180 minutes)

- Ceramic (20–90 minutes; cannot be used in doors, sidelites, or any safety locations)

- Filmed safety ceramic ((20–180 minutes)

- Filmed wired glass (20–90 minutes)

- Traditional wired glass (20–90 minutes; cannot be used in doors, sidelites, or any safety locations)

- Specialty fire-protective (45 minutes rating)

- Heat-reflective specialty tempered glass (20–45 minutes rating; AHJ approval is required for 45-minute applications)

- Specialty tempered glass (20 minutes)

Meanwhile, fire-resistive glazing includes the following products:

- Fire-resistive tempered units (up to 2 hours)

- Fire-resistive annealed multilaminates (up to 2 hours)

Fire-Resistive Door Glazing and Temperature Rise Doors

Doors with the additional function of limiting heat transfer from one side to the other are often referred to as temperature rise doors. They are typically listed for 250°F, 450°F, or 650°F ratings.

They protect by preventing the rise of ambient temperature on the non-fire side of the door. This safety feature allows occupants to safely pass by the door toward the exit if temperatures reach high levels during a fire.

Titan Metal Products offers temperature rise doors for both interior and exterior applications. The Builders Series 60-90-minute temperature rise doors are full-vision doors with a maximum door height of 10 feet. They can easily integrate with the GPX® Architectural Series wall system for a complete 1–2-hour fire-resistive door assembly and glass wall.

Standard door profiles include a 6-inch door top rail, 6-inch door stile, and 2-inch door frame. On the other hand, narrow door profiles include 3 ¾ inches door top rail, 3 ¾ inches door stile, and 1 1/8 inches door frame. Both profile options include a 10-inch ADA-compliant bottom rail, which can be modified with AHJ approval.

Meanwhile, the Builders Series 3-hour temperature rise doors are tested to NFPA 252, UL10B, and UL10C and certified by UL and Intertek. The doors are available in sizes of up to 48 inches x 96 inches and door thickness of 1.75 inches to 3 inches. They also come with vision lites of up to 100 square inches.

Understanding Door Glazing

While fire-protective glazing and fire-resistive glazing are often confused for one another, these two are different. Each has its own features and is governed by different requirements. These two types of door glazing differ in their performance features, applications, and test standards.

Understanding their differences can guide you in choosing the right doors and frames for your building. If you need fire-protective or fire-resistive doors to tighten your fire protection measures and building safety, Titan Metal Products offers fire-rated doors with custom fabrication.

Contact us today to learn more about our fire-rated door assemblies!